Resensys High-Rate Strain SenSpot Sensors Deployed on Robert O Norris Bridge in White Stone, Virginia

On October 12th 2015, Resensys was tasked by the Virginia Department of Transportation to the Robert O Norris Bridge in White Stone, Virginia. Guiding traffic over Rappahannock River, the 50+ year old structure is nearly 10,000 feet in length, carrying over 11,000 vehicles across it every day. Assisted by AI Engineers, the Resensys team monitored the strain in 24 floor beams and one girder web as two trucks passed over the bridge, side by side. They then continued to monitor the data from the sensors with the flow of daily traffic.

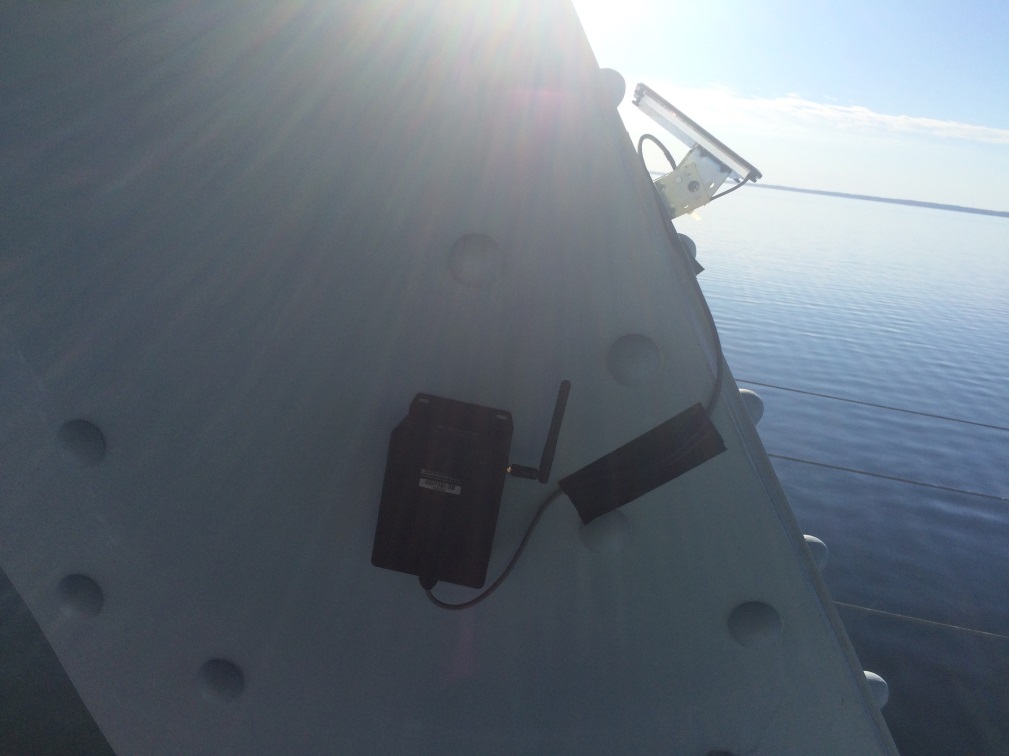

One of five solar powered signal repeaters.

One of five solar powered signal repeaters.

Over the course of three days, Resensys deployed their structural health monitoring system along different spans of the bridge. They then had two trucks drive along the bridge as they recorded the results transmitted wirelessly by their SeniMax data loggers and remote communication gateways. This data gives the structural engineers a good idea of how certain types of traffic affects the strain in different parts of the bridge. Using this data, any potential defects in the bridge that are not visible can be monitored. For large structures like the Robert O Norris Bridge, using Resensys’s technology also significantly reduces the man-power to physically inspect a bridge for any physical defects.

Resensys High Rate Strain SenSpot Sensors placed along Norris Bridge.

Using a control such as trucks with a known weight driving across the bridge, helps Resensys and their clients better understand the capabilities and strengths/weaknesses of a bridge. Different data is collected from multiple trials, consisting of when the trucks drive on different positions of the bridge and drive at different speeds.

The trucks used for the strain test being prepared.