Tower Monitoring Systems Implementation for Cell Towers and Transmission Lines

The collapse of a 2,000-foot transmission tower in Arkansas in 2013 sent shockwaves through the utility industry, highlighting the critical need for continuous tower monitoring systems. This disastrous failure, which occurred without warning, could have been prevented through proper structural health monitoring that detected the progressive guy wire fatigue months before the collapse.

Today’s vertical infrastructure from cellular communication towers to electrical transmission lines faces unprecedented challenges. Aging materials, extreme weather events, and increased loading demands require sophisticated tower monitoring systems that provide real-time structural intelligence. The difference between proactive monitoring and reactive maintenance often determines whether minor issues are addressed during scheduled maintenance or become headline-making disasters.

Modern tower monitoring technologies have evolved to provide comprehensive structural health assessment for all types of vertical infrastructure, enabling operators to protect assets worth millions while ensuring continuous service delivery and public safety.

Understanding Tower Infrastructure Monitoring Needs

The Critical Nature of Tower Structures

Tower infrastructure represents some of our most vulnerable yet essential assets. Unlike bridges or buildings with multiple load paths and redundancy, towers typically rely on precisely balanced structural systems where the failure of a single critical component can trigger catastrophic collapse.

Cell Tower Structural Challenges:

- Wind Loading Dynamics: Towers experience complex wind patterns that create fatigue stress in structural members and foundation systems

- Equipment Loading Changes: Continuous addition of antennas and equipment alters structural dynamics and load distributions

- Foundation Settlement: Differential settlement affects guy wire tensions and structural alignment

- Corrosion Progression: Environmental exposure accelerates material degradation in critical connection points

Transmission Tower Unique Requirements:

- Conductor Loading: Ice accumulation and wind loading on transmission lines create extreme forces transmitted to tower structures

- Electrical Interference: Monitoring systems must operate reliably in high-voltage electromagnetic environments

- Remote Location Challenges: Many towers are located in areas with limited access for maintenance and inspection

- System Reliability Demands: Power grid stability depends on transmission tower structural integrity

Monitoring Parameter Requirements

Effective tower monitoring systems must track multiple structural parameters simultaneously to provide comprehensive condition assessment:

Structural Strain Monitoring: Critical for detecting stress concentrations in tower legs, bracing members, and connection points where fatigue cracks typically initiate.

Dynamic Response Analysis: Tower vibration characteristics change as structural integrity degrades, providing early warning indicators months before visible damage appears.

Foundation and Anchor Monitoring: Guy wire tensions, foundation settlement, and anchor displacement directly affect tower stability and require continuous tracking.

Environmental Correlation: Wind speed, direction, temperature, and ice loading data enable proper interpretation of structural response measurements.

Tower Monitoring Systems Architecture

Wireless Sensor Network Design

Modern tower monitoring implementations leverage advanced wireless sensor networks that remove the complexity and cost of traditional wired systems while providing superior monitoring capabilities.

Multi-Parameter Sensor Integration:

- Wireless Strain Sensors: Monitor structural member stress levels with temperature compensation and long-term stability

- Wireless Accelerometers: Track tower dynamic response and detect changes in natural frequencies indicating structural degradation

- Wireless Tilt Sensors: Monitor foundation movement and guy wire anchor displacement with high precision

- Environmental Sensors: Provide wind, temperature, and humidity data for proper structural response interpretation

Power Management Solutions

Tower monitoring systems must operate reliably for years without maintenance, requiring sophisticated power management strategies:

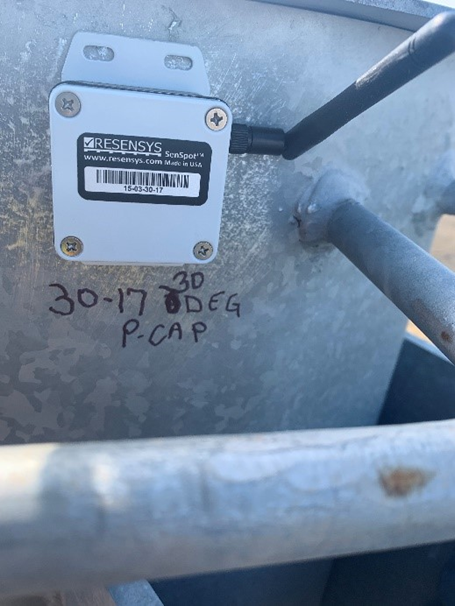

Ultra-Low Power Sensor Design: Advanced wireless sensors like SenSpot™ technology achieve 10+ year battery life through optimized power consumption algorithms and duty cycling.

Battery Technology Selection: Lithium primary batteries provide reliable long-term power in extreme temperature conditions typical of tower installations.

Implementation Strategies by Tower Type

Cell Tower Monitoring Implementation

Cellular communication towers require specialized tower monitoring systems that address unique operational and environmental challenges:

Structural Health Assessment:

- Base Section Monitoring: Strain sensors on tower legs detect overloading and fatigue development in critical lower sections

- Guy Wire Tension Monitoring: Load cells or strain sensors track guy wire tensions that change due to foundation movement or thermal effects

- Antenna Loading Analysis: Strain monitoring quantifies loads from antenna additions and modifications

Installation Considerations:

- RF Interference Mitigation: Sensor electronics must operate reliably in high RF environments without affecting communication systems

- Climbing Safety: Sensor installations should minimize tower climber exposure during installation and maintenance

- Service Continuity: Monitoring system installation cannot interrupt cellular service operations

Transmission Tower Monitoring Systems

Electrical transmission towers present unique challenges requiring specialized tower monitoring systems approaches:

High-Voltage Environment Considerations:

- Electrical Isolation: All monitoring components must maintain proper electrical isolation from energized conductors

- EMF Immunity: Sensors and communication systems must operate reliably in extreme electromagnetic fields

- Grounding Requirements: Proper grounding prevents monitoring system interference with power system protection schemes

Critical Monitoring Parameters:

- Conductor Tension Monitoring: Track transmission line tensions that vary with temperature and loading conditions

- Tower Deflection Measurement: Monitor tower movement under wind and ice loading to ensure clearance maintenance

- Insulator String Monitoring: Detect mechanical stress in critical insulator assemblies

Weather Loading Analysis:

- Ice Loading Detection: Strain measurements quantify ice accumulation on conductors and structures

- Wind Response Monitoring: Accelerometers track dynamic response during high wind events

- Temperature Compensation: Accurate thermal correction for all measurements affected by ambient conditions

Specialized Tower Applications

Broadcast Tower Monitoring:

- Antenna Pattern Integrity: Structural deformation affects broadcast coverage patterns requiring precise deflection monitoring

- Guy Wire Optimization: Maintain proper guy wire tensions for optimal antenna performance and structural stability

- Lightning Protection: Monitor lightning rod and grounding system integrity through continuous resistance measurements

Wind Measurement Tower Monitoring:

- Calibration Stability: Ensure meteorological measurement accuracy through structural stability monitoring

- Sensor Platform Integrity: Monitor anemometer mounting platforms for vibration and deflection that affect measurements

- Data Quality Assurance: Correlate structural measurements with wind data to identify measurement artifacts

Technical Specifications and Performance Metrics

Sensor Performance Requirements

Tower monitoring systems demand high-performance sensors capable of reliable operation in challenging environments:

| Parameter | Specification | Application |

| Strain Accuracy | 1 µε | Critical stress detection |

| Temperature Range | -40°C to +65°C | All-weather operation |

| Acceleration Range | ±8g | Dynamic response analysis |

| Battery Life | 10+ years | Maintenance-free operation |

| Communication Range | 300–400 meter line-of-sight | Remote tower connectivity |

Data Acquisition and Analysis

Real-Time Processing Capabilities:

- Data Storage: Local buffering with configurable retention periods for detailed analysis

- Alert Generation: Immediate notification when measurements exceed predefined thresholds

- Trend Analysis: Automated long-term trend detection for predictive maintenance planning

Advanced Analytics Features:

- Modal Analysis: Automatic natural frequency extraction and change detection

- Fatigue Analysis: Stress cycle counting and remaining life estimation

- Environmental Correlation: Automatic compensation for temperature and wind effects

- Anomaly Detection: Machine learning algorithms identify unusual behavior patterns

Installation and Deployment Best Practices

Pre-Installation Planning

Successful tower monitoring implementation requires comprehensive planning addressing site-specific challenges:

Structural Assessment:

- Load Path Analysis: Identify critical structural members requiring monitoring priority

- Access Planning: Minimize tower climbing requirements through strategic sensor placement

- Environmental Evaluation: Assess wind, ice, and temperature conditions affecting sensor selection

Installation Procedures

Safety Protocols:

- Tower Climbing Safety: Follow OSHA and industry best practices for tower worker protection

- Electrical Safety: Implement proper lockout/tagout procedures for transmission tower work

- RF Exposure Limits: Ensure compliance with RF exposure limits during cell tower installations

Sensor Mounting Techniques:

- Strain Sensor Installation: Proper surface preparation and adhesive application for long-term reliability

- Weather Protection: Sealed enclosures prevent moisture intrusion

Commissioning and Validation

System Validation Procedures:

- Sensor Calibration: Verify measurement accuracy using traceable calibration standards

- Communication Testing: Confirm reliable data transmission under various environmental conditions

- Alert System Verification: Test all alarm and notification systems before system handover

Baseline Data Collection:

- Environmental Correlation: Collect comprehensive baseline data across seasonal variations

- Load Testing: Document structural response under known loading conditions

- System Integration: Verify proper integration with existing maintenance management systems

Advanced Features and Future Developments

Machine Learning Integration

Modern tower monitoring systems increasingly use artificial intelligence for enhanced predictive capabilities:

Automated Pattern Recognition: Machine learning algorithms identify subtle changes in structural behaviour that indicate developing problems before traditional threshold-based systems trigger alerts.

Predictive Maintenance Optimization: AI systems analyses historical maintenance data combined with monitoring results to optimize maintenance scheduling and resource allocation.

False Alarm Reduction: Advanced algorithms distinguish between environmental effects and genuine structural changes, reducing unnecessary maintenance responses by up to 60%.

Integration with Digital Twins

Virtual Tower Modeling: Digital twin technology combines real-time monitoring data with detailed structural models to predict tower behaviour under various loading scenarios.

Scenario Analysis: Engineers can evaluate “what-if” scenarios for equipment additions, extreme weather events, or maintenance activities before implementation.

Lifecycle Management: Digital twins track structural degradation over time, enabling accurate remaining life assessments and replacement planning.

Troubleshooting and Maintenance

Common Implementation Challenges

- Power Line Noise: High-voltage transmission lines generate electromagnetic interference requiring proper filtering and grounding

- Corrosion Protection: Coastal or industrial environments require enhanced corrosion protection for sensor hardware

- Wildlife Interference: Bird and insect activity can affect sensors requiring appropriate protective measures

Maintenance Best Practices

- Annual Inspections: Visual inspection of sensor installations and communication equipment

- Firmware Updates: Regular sensor firmware updates provide enhanced features and bug fixes

- Software Upgrades: Data analysis platform updates improve analytical capabilities and user interfaces

Conclusion

Tower monitoring systems have evolved from luxury add-ons to essential infrastructure protection tools. The combination of wireless sensor technology, advanced analytics, and cloud-based data management provides tower operators with unprecedented visibility into structural health and performance.

Successful implementation requires careful planning, proper sensor selection, and systematic deployment approaches according to specific tower types and applications. The investment in comprehensive tower monitoring pays through extended asset life, reduced emergency maintenance costs, and improved safety outcomes.

The future of tower infrastructure management belongs to organizations that embrace continuous monitoring technologies. As towers age and face increasing environmental challenges, the ability to detect problems before they become emergencies will differentiate successful operators from those struggling with reactive maintenance approaches.

Modern wireless monitoring systems like SenSpot™ technology provide the reliability, longevity, and analytical capabilities necessary for effective tower structural health management. By implementing complete monitoring strategies today, tower operators position themselves for optimal asset performance and safety outcomes throughout their infrastructure lifecycle.

Ready to implement comprehensive tower monitoring systems for your vertical infrastructure? Our wireless monitoring solutions provide the continuous structural health visibility necessary for optimal tower management, safety, and performance. Contact our technical experts to discuss customized monitoring strategies for specific tower and operational requirements.