Geotechnical Monitoring Parameters and Instrumentation Best Practices for Infrastructure Projects

Modern infrastructure projects demand precise geotechnical mon itoring to ensure safety, longevity, and performance. With aging infrastructure systems across the globe, geotechnical engineering professionals must implement comprehensive monitoring strategies that capture critical parameters and provide actionable insights for informed decision-making.

This extensive guide explores essential remote geotechnical monitoring parameters and establishes best practices for geotechnical instrumentation in today’s infrastructure projects.

Understanding Remote Geotechnical Monitoring in Modern Infrastructure

Geotechnical monitoring involves the systematic measurement and analysis of ground behaviour, structural response, and environmental conditions that affect infrastructure performance. As infrastructure systems age and face increasing loads, effective geotechnical instrumentation monitoring becomes crucial for preventing failures and optimizing maintenance strategies.

The integration of advanced wireless geotechnical sensors and real-time data collection has transformed traditional geotechnical monitoring approaches, enabling continuous assessment of critical parameters that were previously measured only through periodic manual inspections.

- Foundation settlement analysis

- Retaining wall performance assessment

- Bridge pier and abutment monitoring

- Tunnel liner stress evaluation

Core Geotechnical Monitoring Parameters

1. Strain and Stress Monitoring

Strain measurement forms the foundation of structural geotechnical monitoring, providing direct insights into material behaviour under various loading conditions.

Critical Measurements:

- Longitudinal and transverse strain in structural elements

- Compressive and tensile stress in concrete and steel components

- Differential strain patterns indicating uneven loading or settlement

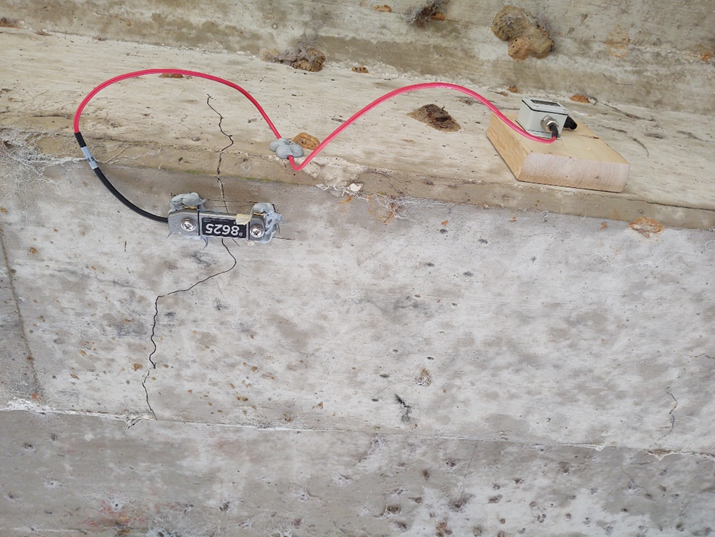

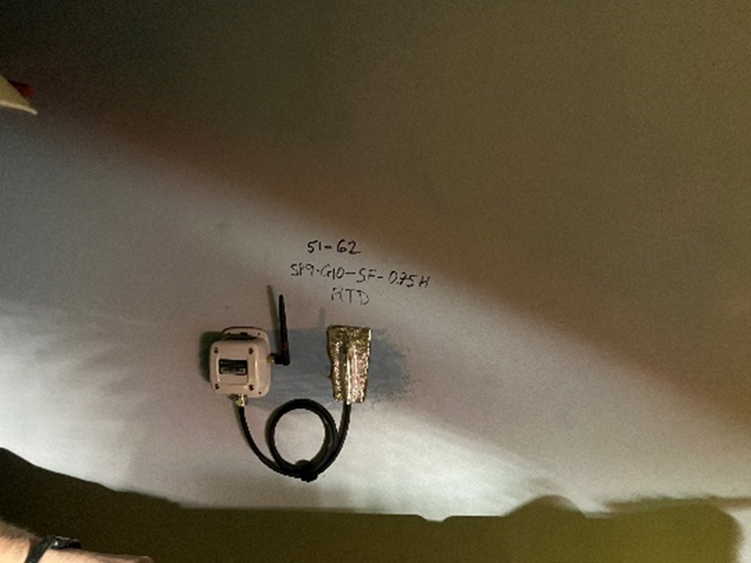

SenSpot™ wireless strain gauges can achieve precision levels of 1 micro-strains, enabling detection of minute changes that precede structural issues.

2. Displacement and Settlement Monitoring

Displacement monitoring tracks movement and crack width, providing essential data for understanding ground behaviour and structural response.

Primary Parameters:

- Vertical settlement of foundations and embankments

- Lateral displacement of retaining structures

- Joint movement in segmented structures

- Surface subsidence in tunnelling projects

- Crack width changes

Monitoring Applications:

- Building and bridge foundation settlement

- Slope stability assessment

- Excavation-induced ground movement

- Long-term creep behaviour in soft soils

3. Inclination and Tilt Monitoring

Tilt measurement using wireless inclinometers for remote geotechnical monitoring provides critical information about structural stability and ground movement patterns.

Essential Measurements:

- Angular displacement of structural elements

- Slope angle changes in embankments and cuts

- Foundation rotation under eccentric loading

- Wall deflection and rotation patterns

Applications in Infrastructure:

- Bridge pier inclination monitoring

- Retaining wall stability assessment

- Building tilt detection

- Dam abutment monitoring

4. Vibration and Dynamic Response

Dynamic monitoring captures structural response to various loading conditions, providing insights into system health and performance.

Key Parameters:

- Acceleration measurements in multiple axes

- Frequency domain analysis for modal identification

- Vibration amplitude and duration

- Dynamic amplification factors

Critical Applications:

- Bridge dynamic response under traffic loads

- Seismic response monitoring

- Construction-induced vibration assessment

- Structural health evaluation through modal analysis

Know More about Ground Vibration Monitoring

5. Environmental Parameters

Environmental conditions significantly influence geotechnical behavior and structural performance.

Essential Environmental Monitoring:

- Temperature variations affecting thermal expansion

- Humidity levels impacting material properties

- Freeze-thaw cycle documentation

- Groundwater level fluctuations

Geotechnical Instrumentation Best Practices

Strategic Sensor Placement and Layout

Effective geotechnical instrumentation requires careful consideration of sensor placement to capture representative data while optimizing coverage.

Placement Principles:

- Position sensors at critical load paths and potential failure zones

- Ensure adequate spatial distribution for overall monitoring

- Consider accessibility for installation and maintenance

- Account for environmental protection requirements

Data Acquisition and Management

Resensys provides remote geotechnical monitoring that is relied on robust data acquisition systems that provide reliable, continuous measurement capabilities.

Best Practices for Data Systems:

- Implement synchronized data collection across all sensors

- Establish appropriate sampling frequencies for different parameters

- Design data storage systems with adequate capacity and backup

- Create automated alert systems for threshold exceedances

Quality Assurance Protocols:

- Regular calibration verification and sensor health checks before installation

- Data validation procedures to identify and correct anomalies

- Documentation of environmental conditions affecting measurements

- Standardized data processing and analysis procedures

Technology Selection Criteria

Choosing appropriate geotechnical instrumentation technology requires careful evaluation of project requirements, environmental conditions, and performance specifications.

Critical Selection Factors:

- Measurement accuracy and precision requirements

- Operating environment and durability needs

- Power consumption and maintenance requirements

- Data transmission capabilities and real-time access needs

Long-term Monitoring Strategies

Successful geotechnical monitoring programs require sustainable approaches that maintain data quality over extended periods.

Sustainability Considerations:

- Select instrumentation with proven long-term stability

- Implement preventive maintenance schedules

- Plan for technology updates and system evolution

- Establish data archiving and retrieval procedures

Performance Optimization:

- Regular review of monitoring objectives and parameters

- Adjustment of sampling frequencies based on observed behaviour

- Integration of new sensor technologies as they become available

- Continuous improvement of analysis and interpretation methods

Advanced Applications in Infrastructure Monitoring

Bridge Foundation Monitoring

Geotechnical instrumentation plays a crucial role in bridge foundation assessment, particularly for scour monitoring and settlement detection.

Critical Parameters:

- Foundation settlement and differential movement

- Scour depth around bridge piers

- Lateral earth pressure on abutments

- Thermal expansion effects

Tunnel Construction Monitoring

Underground construction requires comprehensive geotechnical monitoring to ensure safety and minimize ground disturbance.

Key Measurements:

- Ground movement during excavation

- Liner stress and deformation

- Groundwater pressure changes

- Surface settlement above tunnel alignment

Dam and Levee Monitoring

Critical infrastructure like dams requires continuous geotechnical monitoring to ensure public safety and regulatory compliance.

Essential Parameters:

- Foundation seepage and pore pressure

- Embankment settlement and displacement

- Abutment stability and movement

- Internal stress distribution

Implementation Guidelines for Successful Projects

Project Planning Phase

- Define clear monitoring objectives aligned with project risks

- Establish baseline measurements before construction begins

- Develop comprehensive instrumentation plans with redundancy

- Create data management protocols and analysis procedures

Installation Best Practices

- Follow SenSpot™ specifications for sensor installation

- Document installation procedures and environmental conditions

- Verify sensor functionality before system deployment

- Establish communication protocols and data validation procedures

Ongoing Operations

- Monitor system health and wireless geotechnical sensor performance

- Provide training for personnel responsible for data interpretation

- Establish emergency response procedures for threshold exceedances

Emerging Technologies and Future Trends

The field of geotechnical instrumentation continues to evolve with advances in sensor technology, data analytics, and wireless communications. Emerging trends include:

- Integration of IoT technologies for enhanced connectivity

- Machine learning applications for predictive analytics

- Improved battery technologies extending sensor operational life like those of SenSpot™ sensors

- Enhanced data visualization and real-time dashboard capabilities

Advantages of Resensys Wireless Monitoring systems

- Wireless SenSpot™ Sensor: No wiring, minimal lane closure for installation

- Sensors with 10+ Years Battery Life: No need for battery replacement, maintenance or calibration in the field

- Easy Installation: Self-adhesive (e.g., steel) or Flange-mount (e.g., concrete)

- Quick Testing: Can be installed for short-term testing, easy to remove and reuse on other structures/pipelines and applications

- Long-term Monitoring: Designed to be used for long-term monitoring (e.g., several years)

- Small Size and Lightweight

- Being Suitable for Different Kind of Materials: Can be used on steel, concrete, timber, and composites

- Rugged, Weather Proof and Corrosion Resistant: Can operate in rain, snow, ice, high humidity, salty environment and extreme weather (-40°C to +65°C or -40°F to +150°F)

- Infrastructure Less: Battery Operated, Energy self-sufficient, No need for communication infrastructure at the pipelines

- Provide Data Visualization, Data Analysis and capability with AI/ML algorithms

- Provide Alert Services: Alert generation and management with customizable alert levels, automated structural diagnostics, capability of providing e-mail or text message alerts

- Very High-Resolution sensors

Conclusion

Effective geotechnical monitoring requires careful selection of parameters, strategic instrumentation placement, and implementation of proven best practices. By focusing on essential measurements such as strain, displacement, inclination, and vibration, infrastructure projects can achieve detailed monitoring that supports informed decision-making and preventive maintenance strategies.

The evolution toward wireless geotechnical instrumentation systems offers significant advantages in terms of installation flexibility, long-term reliability, and real-time data access. As infrastructure systems continue to age and face increasing demands, robust geotechnical monitoring becomes essential for ensuring public safety and optimizing asset management.

Ready to implement advanced geotechnical monitoring for your infrastructure project?

Contact Resensys today to learn how our wireless SenSpot™ sensors can provide comprehensive, long-term monitoring solutions for your geotechnical instrumentation needs. Request a consultation to discuss your specific monitoring requirements and discover how our proven technology can enhance your project’s success.

Frequently Asked Questions

Q: What is the typical lifespan of remote geotechnical monitoring instruments?

A: Modern wireless geotechnical sensors can operate for 10+ years on a single battery, while traditional wired systems may require more frequent maintenance. The lifespan depends on environmental conditions, power management, and technology type.

Q: How often should geotechnical monitoring data be reviewed?

A: Critical infrastructure should have real-time monitoring with automated alerts, while routine data review can be conducted weekly or monthly depending on project requirements and risk levels.

Q: What are the key factors in selecting geotechnical monitoring parameters?

A: Parameter selection should be based on project risks, structural design requirements, environmental conditions, and regulatory compliance needs. Critical load paths and potential failure modes should be prioritized.