Structural Health Monitoring Trends Using Industrial Wireless Sensors

As infrastructure systems grow larger, older, and more complex, traditional inspection methods are no longer sufficient to ensure safety, reliability, and performance. Manual inspections, periodic testing, and reactive maintenance approaches often fail to detect early-stage damage or rapidly evolving risks. This has accelerated the global shift toward remote monitoring systems powered by industrial IoT sensors and industrial wireless sensors.

Wireless Structural Health Monitoring (SHM) uses industrial IoT sensors and wireless communication to continuously measure strain, vibration, displacement, and other parameters, enabling real-time assessment of structural safety and performance.

Wireless SHM has evolved beyond simple data collection. Today’s systems combine sensors and automation, low-power wireless communication, cloud-based platforms, and intelligent analytics to deliver continuous, real-time visibility into asset condition. As we move toward 2026 and beyond, wireless SHM is becoming a foundational component of modern industrial monitoring systems using IoT, enabling smarter decisions, predictive maintenance, and long-term asset resilience.

Key Takeaways

- Wireless SHM enables continuous, real-time infrastructure monitoring

- Industrial IoT sensors reduce inspection costs and safety risks

- Remote monitoring systems support predictive maintenance

- Automation and analytics improve early damage detection

- Wireless SHM is becoming essential for modern infrastructure management

The Evolution of Structural Health Monitoring

Historically, SHM relied on wired sensors, periodic site visits, and manual data interpretation. While effective for localized testing, these approaches struggled with scalability, cost, and real-time responsiveness, especially for large or remote infrastructure.

Wireless SHM represents a fundamental shift:

- Elimination of extensive cabling, reducing installation time and disruption

- Scalable deployment across multiple structures or locations

- Continuous monitoring instead of snapshot-based inspections

- Remote access to data from anywhere

The rise of industrial wireless sensors has made it practical to monitor bridges, buildings, utilities, industrial facilities, and transportation networks in near real time, even in harsh or inaccessible environments.

Why Are Industrial Wireless Sensors Important for Structural Monitoring?

At the core of this transformation are industrial wireless sensors designed for structural and environmental monitoring. These sensors are engineered for reliability, accuracy, and long-term operation in demanding conditions.

Modern SHM deployments commonly use sensors that measure:

- Strain and stress in structural members

- Vibration and dynamic response

- Displacement and crack movement

- Tilt and inclination of supports and foundations

- Environmental parameters such as temperature and humidity

By connecting these sensors into an industrial monitoring system using IoT, organizations gain a unified view of structural behavior under operational loads, environmental effects, and extreme events.

How Do Remote Monitoring Systems Improve Infrastructure Safety?

One of the most significant trends in wireless SHM is the widespread adoption of remote monitoring systems. These systems allow asset owners and engineers to track structural performance without being physically present on site.

Key advantages include:

- Real-time alerts when thresholds are exceeded

- Centralized dashboards for multi-site infrastructure portfolios

- Reduced inspection frequency, improving safety and lowering costs

- Faster response to emerging risks

Remote monitoring systems are especially valuable for assets such as bridges, transmission towers, tunnels, retaining walls, and industrial structures where access may be limited or hazardous.

Energy-Efficient and Autonomous Monitoring Technologies

Power management remains one of the most critical challenges in large-scale wireless SHM deployments. Recent advances have focused on making sensors more autonomous and energy efficient.

- Ultra-Low-Power Sensor Design: Modern industrial wireless sensors use optimized electronics and communication protocols to operate on minimal power, extending operational life to more than 10 years without battery replacement.

- Event-Driven Sensing: Instead of transmitting data continuously, sensors can remain in low-power sleep mode and activate only when triggered by specific events, such as excessive vibration, load changes, or abnormal movement. This approach dramatically reduces energy consumption while ensuring critical events are captured.

- Energy Harvesting: Emerging SHM systems increasingly use energy harvesting techniques, such as vibration or solar energy, to supplement or replace batteries. This trend supports truly long-term, maintenance-free remote monitoring systems for infrastructure assets.

AI and Data Intelligence in Structural Monitoring

As sensor networks generate growing volumes of data, sensors and automation must be supported by intelligent data processing. Artificial intelligence and machine learning are becoming integral to modern SHM platforms.

AI-driven capabilities include:

- Anomaly detection to identify unusual structural behavior

- Pattern recognition in vibration or strain data

- Predictive maintenance models that forecast deterioration trends

- Automated damage classification based on historical datasets

By combining industrial IoT sensors with advanced analytics, organizations can shift from reactive repairs to proactive, data-driven maintenance strategies.

Multi-Modal Sensing for Holistic Structural Assessment

Another key trend is the adoption of multi-modal sensing, where different types of sensors are deployed together to provide a comprehensive view of structural performance.

For example:

- Strain sensors quantify load effects

- Vibration sensors capture dynamic response

- Displacement sensors track crack growth

- Tilt sensors monitor foundation movement

- Environmental sensors account for temperature-related effects

This integrated approach improves interpretation accuracy and reduces the risk of misdiagnosis, an essential requirement for safety-critical infrastructure.

Integration with Industrial Monitoring and Automation Systems

Wireless SHM is no longer isolated from broader operational technology ecosystems. Instead, it is increasingly integrated into industrial monitoring systems using IoT and facility management platforms.

This convergence enables:

- Data sharing across maintenance, operations, and engineering teams

- Integration with automation systems and control platforms

- Streamlined compliance reporting and documentation

- Unified visibility across structural, mechanical, and environmental systems

Such integration reinforces the role of SHM as a strategic component of sensors and automation in industrial and infrastructure environments.

Applications Across Infrastructure and Industry

The adoption of industrial wireless sensors for SHM continues to expand across multiple sectors:

- Transportation Infrastructure: Bridges, tunnels, and rail structures benefit from continuous monitoring of strain, vibration, and displacement to manage fatigue, overloads, and long-term deterioration.

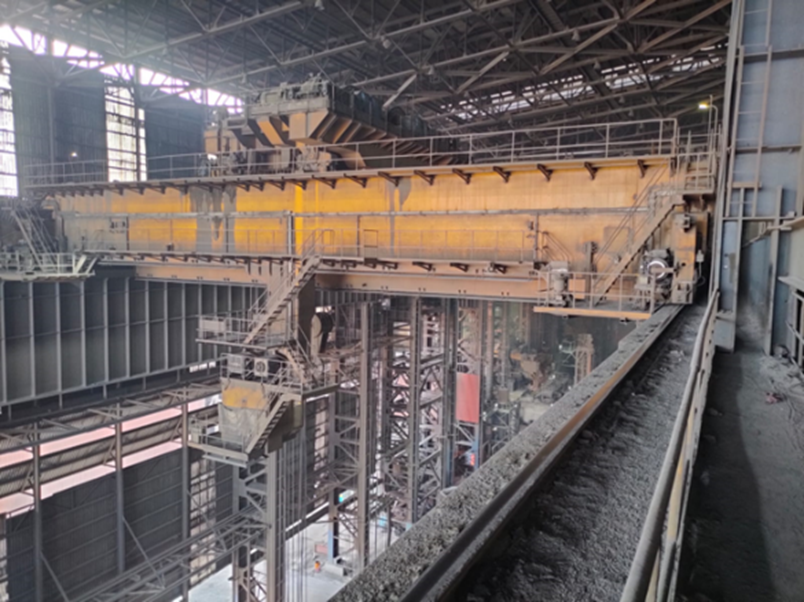

- Industrial Facilities: Factories, processing plants, and energy facilities rely on remote monitoring systems to track structural integrity, equipment interaction, and environmental conditions.

- Utilities and Pipelines: Wireless SHM supports early detection of movement, stress, and environmental impacts that could lead to failures or service disruptions.

- Buildings and Civil Structures: Monitoring tilt, vibration, and deformation improves safety and lifecycle management for high-rise buildings and public infrastructure.

Challenges Facing Wireless SHM Adoption

Despite rapid progress, several challenges remain:

- Power and Longevity: Even with low-power designs, ensuring uninterrupted operation over many years requires careful system planning.

- Data Volume and Network Scalability: High-frequency measurements can generate large datasets, necessitating efficient data handling and network optimization.

- Deployment and Cost Optimization: Strategic sensor placement and scalable architectures are essential to balance cost with monitoring effectiveness.

Industry innovation continues to address these challenges through improved hardware design, smarter communication strategies, and advanced analytics.

Preparing for the Future of Infrastructure Monitoring

Looking ahead, wireless SHM will play an increasingly critical role in infrastructure resilience and asset management. Organizations preparing for the future are:

- Investing in scalable remote monitoring systems

- Adopting industrial IoT sensors for long-term visibility

- Integrating SHM into broader industrial monitoring systems using IoT

- Leveraging automation and analytics to support informed decision-making

As regulatory requirements, sustainability goals, and operational complexity increase, wireless SHM provides the data foundation needed to manage risk and optimize performance.

Advantages of Resensys Wireless Monitoring systems

- Wireless SenSpot™ Sensor: No wiring, minimal lane closure for installation

- Sensors with 10+ Years Battery Life: No need for battery replacement, maintenance or calibration in the field

- Easy Installation: Self-adhesive (e.g., steel) or Flange-mount (e.g., concrete)

- Quick Testing: Can be installed for short-term testing, easy to remove and reuse on other structures/pipelines and applications

- Long-term Monitoring: Designed to be used for long-term monitoring (e.g., several years)

- Small Size and Lightweight

- Being Suitable for Different Kind of Materials: Can be used on steel, concrete, timber, and composites

- Rugged, Weather Proof and Corrosion Resistant: Can operate in rain, snow, ice, high humidity, salty environment and extreme weather (-40°C to +65°C or -40°F to +150°F)

- Infrastructure Less: Battery Operated, Energy self-sufficient, No need for communication infrastructure at the pipelines

- Provide Data Visualization, Data Analysis and capability with AI/ML algorithms

- Provide Alert Services: Alert generation and management with customizable alert levels, automated structural diagnostics, capability of providing e-mail or text message alerts

- Very High-Resolution sensors

- Compatible with 3rd party sensors

Conclusion

The latest trends in wireless structural health monitoring highlight a clear direction: smarter sensors, autonomous operation, and intelligent data use are redefining how infrastructure is monitored and maintained. By combining industrial wireless sensors, remote monitoring systems, and sensors and automation, organizations can move beyond reactive maintenance toward predictive, data-driven infrastructure management.

Wireless SHM is no longer an emerging technology, it is becoming an essential tool for ensuring the safety, reliability, and longevity of critical assets in an increasingly connected world.

Learn more about Resensys’ industrial wireless sensors and remote monitoring systems designed for scalable, real-time structural health monitoring.