Home > Products > SenSpot™ > Wireless Strain Gauge SenSpot™

Wireless Strain Gauge SenSpot™ sensors offer a breakthrough technology for wireless strain measurement, enabling real-time and long-term monitoring of structural integrity. Stress and strain sensing are an integral part of most structural condition and strain monitoring system deployments used in bridges, buildings, and critical infrastructure.

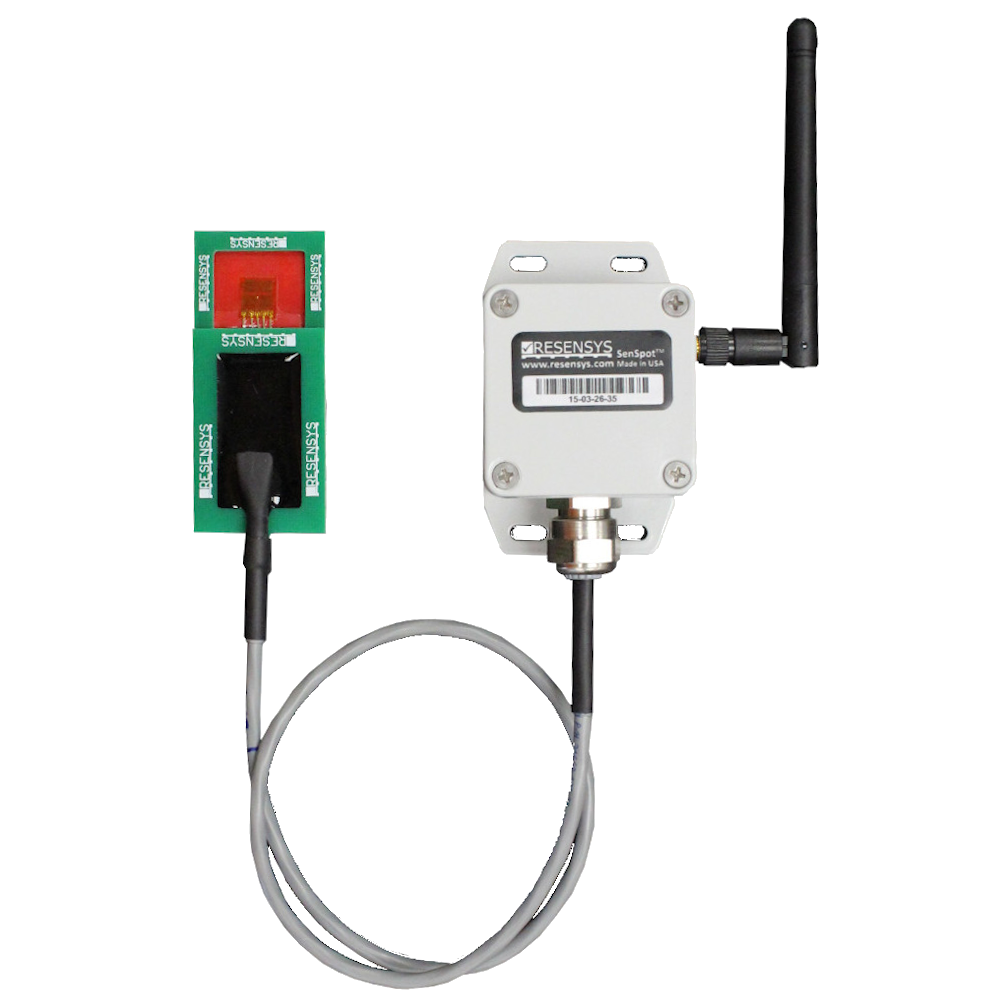

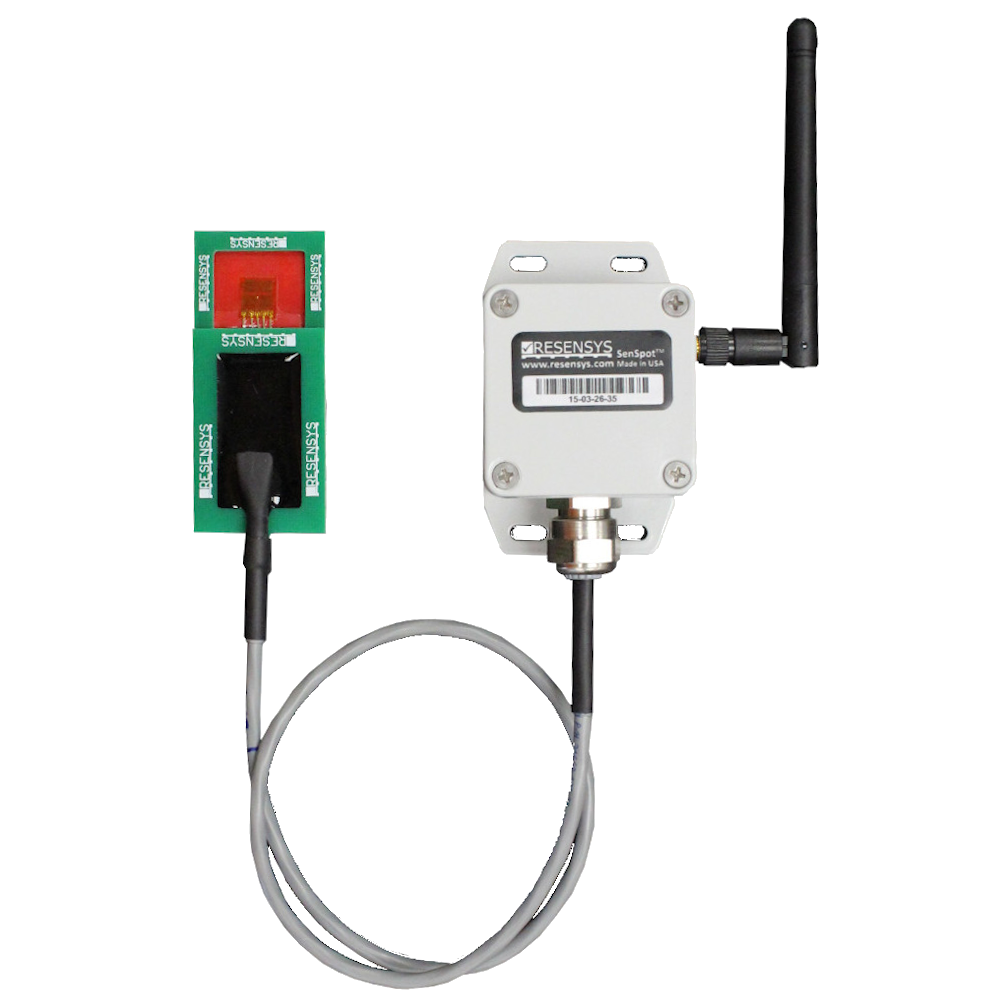

SenSpot™ wireless strain gauge sensor uses Resensys’ proprietary sensing, scheduling, and ultra-low-power synchronization technology to deliver reliable, high-accuracy strain data over extended periods. Designed for both short-term assessments and permanent installations, SenSpot™ sensors provide consistent performance in demanding structural monitoring environments.

SenSpot™ strain gauge sensors are engineered to operate maintenance-free for up to a decade. After installation, these wireless strain gauge sensors do not need in-field calibration, battery replacement, or any other maintenance during their service life, making them ideal for long-term strain monitoring systems where access is limited and reliability is critical.

without battery replacement

1-µStrain resolution

self-adhesive(e.g. steel)/

flange-mount(e.g. concrete)

1 km free space

easy to reuse in other places

record unusual strain event

• Long battery lifetime (10 years, typical) • Wireless communication (IEEE 802.15).• Small size and light weight• High Accuracy: 1 microstrain typical resolution• High-rate data transmission triggered by sudden strain changes• Adjustable transmission interval• Easy mounting• High compatibility

• Long- term and continuous monitoring of strain (stress). • Detecting short-lived and transient high-strain events, e.g., caused by fast moving trucks on highway bridges or by turbulence on airframes. • Monitors and measures strain for highway bridges, airframes, pipelines, machinery, cranes, tunnels etc. • Conducts structural fatigue analysis, truck tests, and bridge load ratings. • Assess structural health in nuclear powerplants, wind turbines, and railway infrastructure. • Used in building monitoring systems, dam monitoring systems, and for monitoring retaining walls to accurately measure strain and ensure structural integrity.

• Long lifetime: minimum expected life without battery replacement 10 years

• Lightweight: about 147 g (5.19 oz.)

• Wireless transmitter: 120 g (4.23 oz.)

• Cable (1ft): 10 g (0.35oz.)

• Strain sensing element: 17 g (0.6 oz.)

• Easy mounting:

○ Self-adhesive, no drilling is required (e.g. steel)

○ Flange-mount, drilling is required (e.g. concrete)

○ Quick installation, 1-2 minutes

• High accuracy: 1-µStrain resolution

• Wide working temperature: -40 to +65°C (-40 °F to +150°F)

• Long communication range: 1.0km free space

• Small size:

○ Wireless transmitter: 50mm (1.96”) x 50mm (1.96”) x 34mm (1.34”)

○ Strain Gauge sensor: 76.2mm (3”) x 33.4mm (1.30”) x 10mm (0.4”)

• Complementary data collected: temperature, battery voltage, etc.

• (Optional) High sampling rate; instant data transmission triggered by strain spikes:

○ A balance between power consumption and performance.

○ Perfect for detecting event and recording the waveform of a sudden strain change.

○ The triggering threshold is adjustable from 16µStrain to 512µStrain; the sampling rate can be changed from 10ms to 200ms.